Lowering Costs and Improving Efficiency

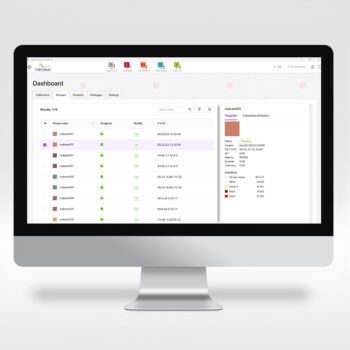

Tools like spectrophotometers and Colibri software help masterbatchers reduce costs by improving efficiency and accuracy while keeping costs down. A streamlined color management program limits the amount of waste caused by off-color products and, through custom integrations with ERPs and PLMs, optimizes ingredient usage based on specified criteria such as cost, specific additives, and more.

Fewer mistakes mean your customer receives their order faster and lets them know they can rely on you to deliver the materials they need with the quality and accuracy their business requires.

Read Our Customer Success Story