Understanding Metamerism: The Subtle Nuances of Color Matching

Metamerism is an intriguing and critical concept if you work with color. Its effects permeate various aspects of color formulation and production, making it an essential consideration in industries where precise color matching is vital. While those familiar with color science may have encountered this phenomenon, its nuances and implications for product color quality deserve a deeper exploration.

“Controlling metamerism plays a big role in ensuring product quality,” says Monica Paul, a veteran within the textile and apparel industry and current Inside Sales Representative at Datacolor. “A true measure of excellence in color management is maintaining consistency, and part of that is addressing metamerism. It’s key to delivering products that meet the highest standards of color accuracy.”

What is Metamerism?

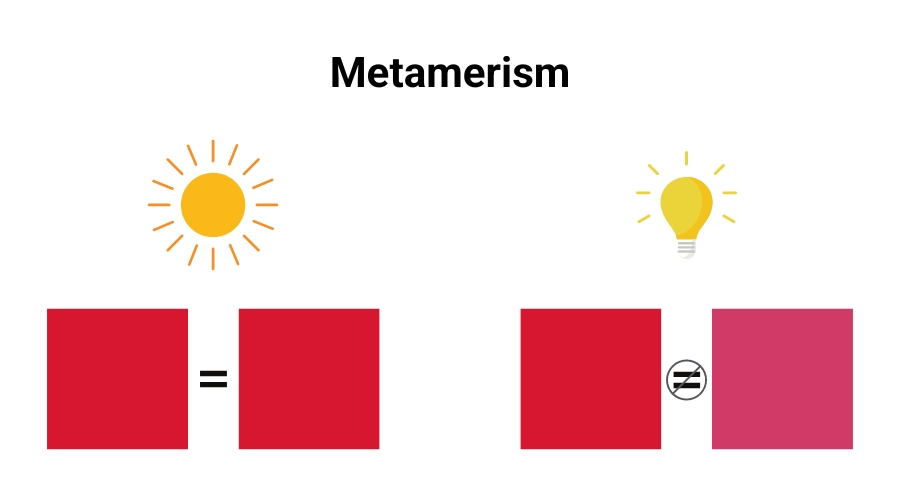

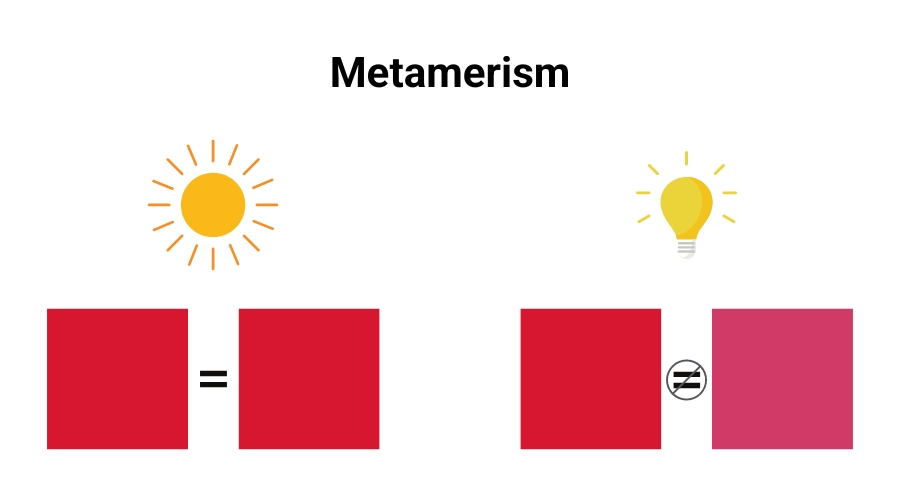

Metamerism is the phenomenon where two objects appear to match in color under one lighting condition but look different under another due to differences in their spectral reflectance. This is called a metameric pair. Simply put, metameric objects look identical under one light source but reveal their true differences under another. This visual match can occur under some light sources even though the objects have different spectral reflectance factors, meaning their spectral curves—the graphs showing how they reflect light across the spectrum—differ.

Example 1

Metamerism is always considered within the framework of the CIE (Commission Internationale de l’Eclairage) colorimetric system. This system hinges on a “color triplet”, which includes:

- A Light Source: The illuminant that shines on the object.

- An Object: The item reflecting light to the observer.

- An Observer: The individual perceiving the reflected light.

The interaction between these components defines the color sensation an observer experiences, which can be mathematically represented through the CIE Tristimulus Values. These values are computed using data from standard illuminants (like D65, A, F2), the object’s spectrophotometric measurement, and standard observer data (1931 2° or 1964 10°).

Difference Between Metamerism and Color Inconstancy

Color inconstancy and metamerism are often confused, but they refer to different aspects of color perception under varying lighting conditions.

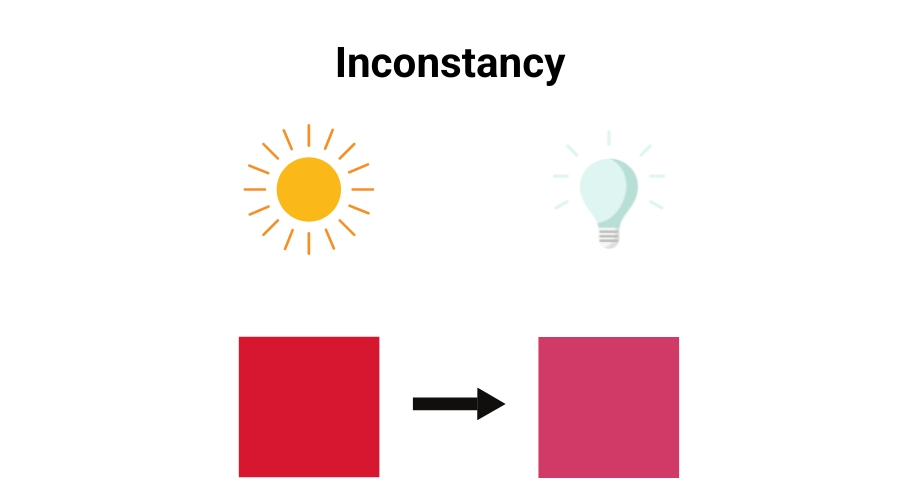

Color inconstancy causes a color to appear different in varying lighting environments. Unlike metamerism, which involves comparing two different colors that look identical under certain lights but different under others, color inconstancy deals with how a single color can shift in appearance depending on the lighting. When a single color changes under different light sources, it is called “flare.” Objects whose color flares less show higher color constancy as opposed to color inconstancy, which flares more.

Datacolor’s Tools software helps color managers handle color inconstancy and metamerism by simulating multiple lighting conditions, allowing users to observe how a color shifts across different environments before going to production. This is essential for ensuring that products appear consistent in all intended viewing conditions, such as retail or daylight. The software provides visual cues and pass/fail criteria to detect significant color changes, helping color managers maintain a stable appearance across various illuminants.

Example 2

Learn More Terms Surrounding Metamerism

Metamerism in Practice

Metamerism becomes particularly significant in real-world applications where color consistency is of high importance, such as in paint and coatings, cosmetics, plastic goods, and textiles.

“Acrylic yarns tend to have a metamerism due to their synthetic nature, generally flaring red in D65,” says Paul, “so they’re only evaluated under the primary light source. As an example, an acrylic sweater designed to match back to a coordinating pant and/or a top can only match under that light source.”

There are two primary types of metamerism that color professionals encounter:

- Illuminant Metamerism: This occurs when two objects match under one light source but not under another, like in Example 1 above. It’s a common issue when products are matched under specific production lighting conditions but appear different under the lighting conditions in which they will be sold or used.

- Observer Metamerism: This type of metamerism arises when two objects match for one observer but not for another. This can happen when different standard observers (CIE 2° or 10°) are used, or when individuals have varying color sensitivity functions, leading to discrepancies in visual assessment.

- Geometric Metamerism: This is a type of observer metamerism that occurs when the observer views a color sample from different angles. It is commonly a problem with metallic or pearlescent materials or materials like carpet and some fabrics.

Testing for Metamerism

Testing for metamerism is an important step for ensuring product color accuracy and consistency. There are two primary methods:

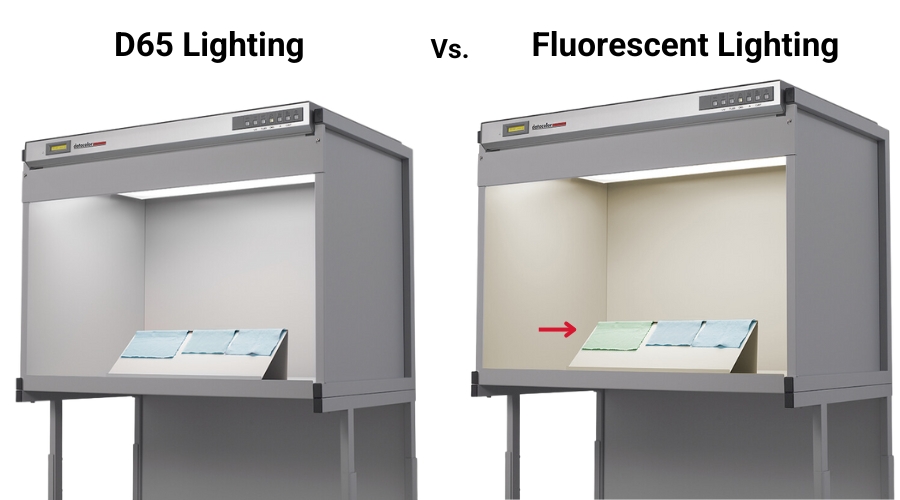

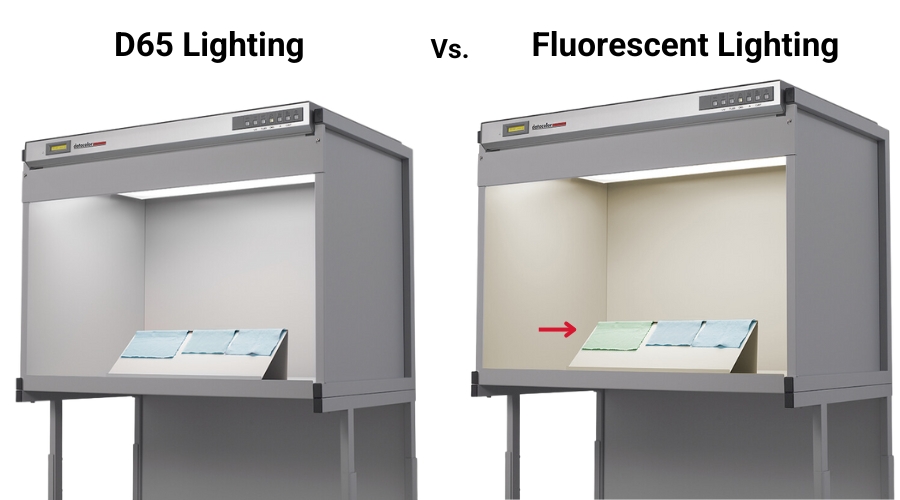

- Visual Testing: This involves observing the objects under different light sources in a controlled environment (like a light booth). If the objects match under the primary light source but not under others, then the objects are metameric. Repeating the test under a third light source can confirm the metamerism.

- Instrumental Testing: Using a spectrophotometer, objects are measured and compared under various illuminant/observer combinations. Spectral curves are analyzed, and if they differ and cross at least three times, the objects are confirmed as metameric. Further calculations of color differences (ΔE) under different conditions help quantify the degree of metamerism.

Paul states that while both methods are generally used in practice, “visual assessment tends to make the final call.”

Example 3

Quantifying Metamerism

Even when metamerism is unavoidable, evaluating its extent can be a key factor in achieving acceptable color matches. Various indices are used to measure the degree of illuminant metamerism:

- CIE Special Metamerism Index: Measures the color difference (ΔE) under a test illuminant, assuming a match under the primary illuminant.

- DIN 6172 Metamerism Index: Adjusts the ΔE for an exact match under the primary illuminant.

- Nimeroff Index of Metamerism: Calculates the difference between spectral curves, offering a measure of the difference without weighting the data.

- Weighted Nimeroff Index: Similar to the Nimeroff Index but with weighting based on CIE color matching functions.

- Root Mean Square (RMS): Computes the square root of the sum of squared color differences (ΔE) across various illuminant/observer combinations, giving an indication of how closely objects will match under different conditions.

How to Control Metamerism

Metamerism can be effectively controlled with the right tools and processes. For example, Datacolor Tools quality control software plays a crucial role in this by calculating a metamerism index, allowing users to identify potential metameric pairs early in the production process. By providing detailed insights into how colors will appear under different lighting conditions, it enables informed decisions to reduce metamerism before manufacturing.

For specific industries, Datacolor Match Textile formulates dye recipes that minimize metamerism by considering various light sources and observer conditions, while Datacolor Match Pigment offers similar control for paints, coatings, and cosmetics by evaluating pigment interactions under different illuminants. In the plastic industry, Colibri’s ColorMatch and ColorQuality modules provide data that alerts operators to the presence of potentially metameric formulations, also via a metamerism index.

And for visual evaluation, there are several styles of lightbooth that suit any office or laboratory within your supply chain, allowing you to assess any colored material with absolute confidence.

Together, these solutions help ensure color consistency across different environments, significantly reducing the risk of metamerism.

Mastering Metamerism

Metamerism is more than just a scientific curiosity; it has practical implications that can impact the success of color-critical products. Understanding its intricacies, the types of metamerism, and how to test and manage it is essential for anyone involved in color formulation and production. By mastering these concepts, professionals can ensure that their products maintain color consistency across different environments, meeting both aesthetic and functional demands.

Chat With An Expert