In the world of plastic masterbatching, precision and consistency are paramount. For masterbatchers, the ability to deliver the same exact color product, batch after batch, is a critical requirement. This consistency not only ensures customer satisfaction but also maintains a competitive edge in a market where converters, extruders, molders, and compounders have many choices for their colored pellet needs. High-quality products at competitive prices are essential, and any deviation can be costly in terms of both time and materials.

The Challenge

One such global masterbatcher with multiple manufacturing locations around the world recently faced a significant challenge: ensuring uniformity and accuracy of colors across all sites while meeting the unique requirements of customers who pay in various currencies. The lack of a centralized database meant that color recipe information and cost calculations were fragmented, leading to inefficiencies and inconsistencies. This scenario necessitated a robust solution that could streamline operations, ensure consistent color, and centralize their data management.

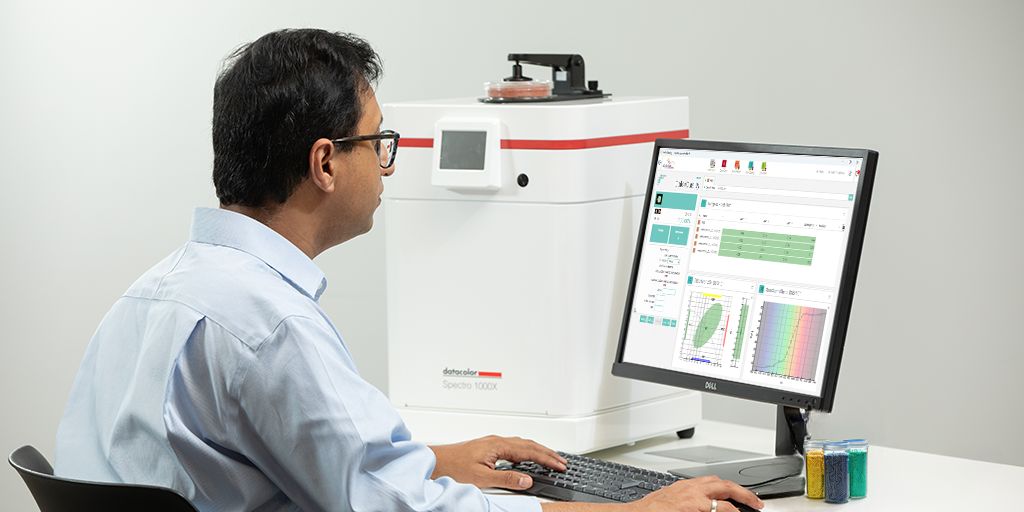

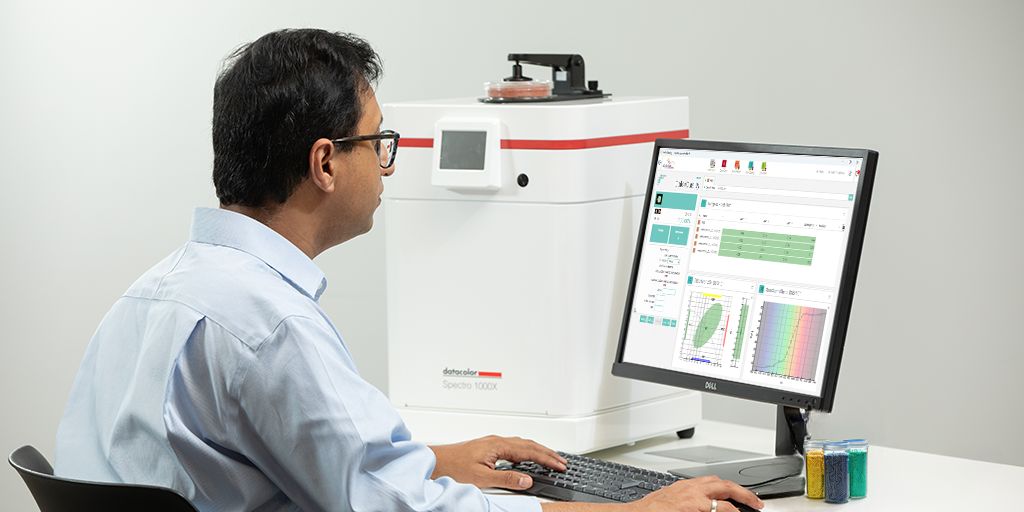

The Solution: Datacolor Colibri Software

To address these challenges, the company sought out an advanced software solution and landed on Datacolor Colibri. Datacolor Colibri provides a centralized database accessible to all manufacturing locations, ensuring that each site can access the same recipe information and calculate costs accurately based on local currencies. This centralization was crucial for optimizing cost savings, but it was also instrumental for consistent color quality of master batch between manufacturing locations.

The masterbatcher leverages Datacolor Colibri software for color quality control (QC) to ensure every batch meets the customer’s specifications, specifically focusing on the delta E (dE) values to ensure that they are within the specified tolerances. Only batches that meet these stringent requirements are sent to customers, ensuring high standards of quality. Additionally, Datacolor Colibri’s ColorMatch module was used to generate new color formulations while leveraging spectrophotometers for precise color measurements of standards.

Integrating Datacolor Colibri for Optimized Workflows

Integrating Datacolor Colibri with the company’s existing systems was a critical step. Each location previously used a local API to help systems communicate, but there was a need for a unified API that could integrate all sites. The integration also had to account for different local currencies and varying costs at each site. The Datacolor Colibri applications team worked closely with the masterbatcher to achieve this integration, incorporating their ERP system to ensure that pricing information from the ERP was available in Datacolor Colibri. This enabled the system to recommend ingredients that met specific price points when creating formulas.

According to the customer, Datacolor’s business analyst, development, and support teams were quick to understand both business and technical requirements ensuring “the integration process was smooth and was well-supported.”

Datacolor Colibri Drives Results

Implementing Datacolor Colibri resulted in substantial time and cost savings for the masterbatcher. The centralized database accelerated the search for existing formulations and prevented the duplication of colors while Datacolor Colibri’s ColorMatch module facilitated the generation of new formulations with higher consistency, enhancing the overall quality of the products.

Datacolor Colibri also enabled the masterbatcher to limit data visibility within the organization to specific people, enhancing data security and management. In addition, the integration of Datacolor Colibri with their ERP further benefited the company by tailoring the software to meet their specific business needs.

Staying Ahead of the Competition

Adoption of Datacolor Colibri software has transformed the masterbatcher’s approach to color management, ensuring accuracy, consistency, and cost efficiency across all its manufacturing locations. The continuous development and support provided by the Datacolor team have positioned the company to stay ahead of its competitors