By Ken Butts

This post is part of a three-part series. Read part 1 here and part 2 here.

To understand the impact of LED on Color and how to design an implementation plan, start with my first blog on this topic as well as my second blog on Evaluating Flare.

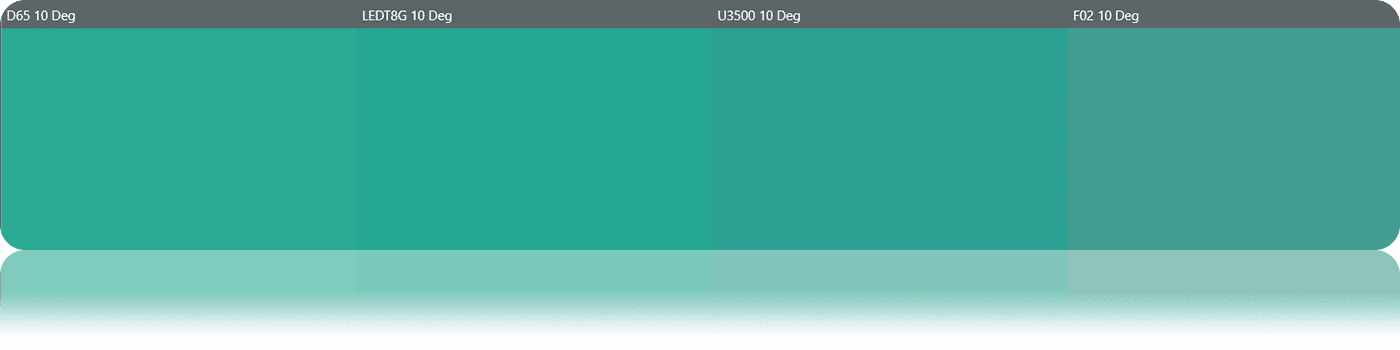

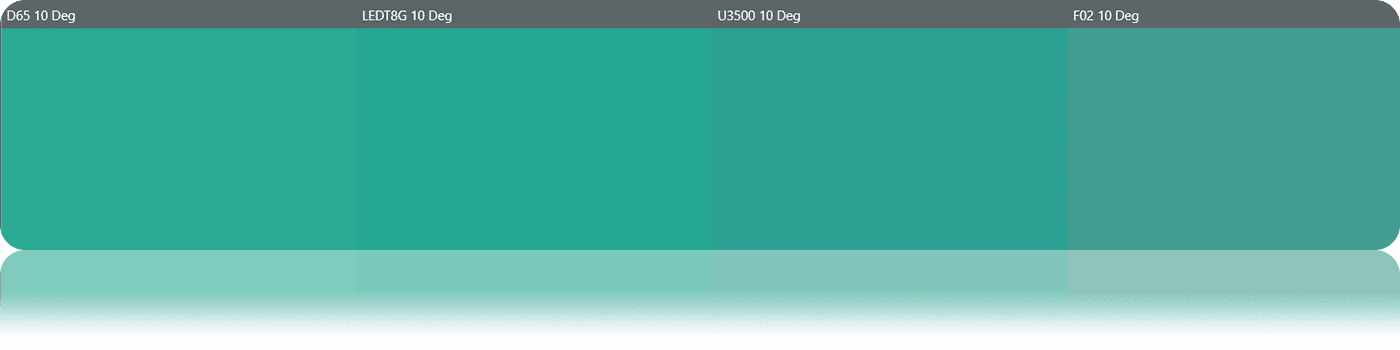

Evaluating Metamerism

The color of a textile material is achieved by using dyes that are appropriate for the fiber type and end use, and unless the standard and sample use the same dyes some level of metamerism will exist. Because garments are manufactured from various fiber types – cotton, polyester, wool, nylon, etc. – it is impossible to use the same dyes for each component, and this means that some degree of metamerism is always present. And even for the same fiber type, sourcing from multiple suppliers may result in the presence of different dyes depending on the processes used by the suppliers. Evaluation of metamerism then is equally as important as evaluating flare, and the same evaluation techniques previously described can be used.

The question when adding LED as a light source for color development is whether the level of metamerism changes enough that the components no longer look like a good match. As with flare, samples can be evaluated visually in a light booth or numerically with color management software. Any problem samples should be evaluated with stakeholders to determine if any corrective action is required, which will typically involve working with the textile supplier to attempt to develop a different dye formula for the component.

An Implementation PLAN

The key to avoiding surprises when implementing LED into the color development process is to start with a well-defined plan. A plan ensures that specific problems can be addressed proactively within the organization rather than having to react to a crisis with product color in the store. The following steps will guide the retail/apparel organization in successful implementation of LED:

- When does the transition to LED need to be complete? Timing determines the urgency of the remaining steps as well as what options may be considered to resolve problems.

- Who will be impacted by the transition to LED, and how will they or their concerns be considered in the evaluation and transition?

- Select a standard CIE LED illuminant that matches as closely as possible the LED used in the environment in which the products will be sold.

- Equip light booths internally and in the supply chain with matching LED lamps.

- Ensure that matching LED illuminant data (SPD) is available in color management software internally and in the supply chain.

- Evaluate standards to determine the impact on flare, then review with stakeholders.

- Evaluate samples to determine the impact on metamerism, then review with stakeholders.

- Based on the results of flare and metamerism evaluation, take one of three approaches for implementation in the global color development supply chain.

Three Approaches to Implementation

Based on the results of the sample analysis, the retail/apparel organization may choose to take one of three approaches to implementing LED in their global color development supply chain:

- Pick an LED for color development that is the same as the LED used in the store, and require its use by vendors and suppliers. This approach may require additional color development for both standards and production colors.

- Pick an LED that is as close to the light source being replaced as possible, and continue using the original light source for color development rather than requiring use of LED. No additional color development work is required with this method, but it may be difficult to find an LED light source that matches the existing one, or to convince the organization to use the preferred LED.

- Adjust color standards to minimize issues due to flare. Changing the dyes used has the potential to produce “color constant” standards that will look the same regardless of light source.

While the most exact, the first option can be the most disruptive because it will require investment in lighting and software in the supply chain to use the selected LED. The second option is the least disruptive since nothing in the current color development process will change, but if another new light source is introduced in the future the entire exercise will need to be repeated. The third option provides the most security for the future in that the goal is to ensure that colors remain the same regardless of what light source is used, but it may be too technically challenging for many supply chain partners.

At times, all the facts that surround a problem or challenge can be so overwhelming that we do not know exactly where to start to find a solution. For some that may be the case regarding implementation of LED. But by following these detailed steps for LED implementation, retail/apparel companies can successfully incorporate LED lighting into their global color development process and ensure an on-going positive experience for their customers.

For a comprehensive discussion of the color management implications of a switch to LED light sources, please contact me directly.