How Do Spectrophotometers Work?

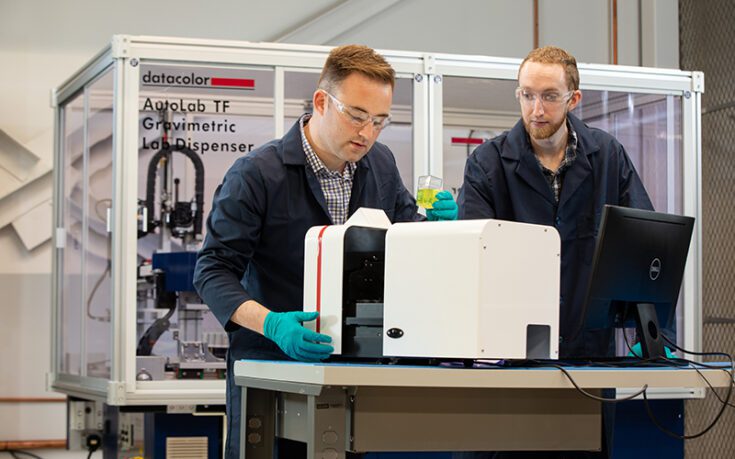

Spectrophotometers measure the wavelengths of light absorbed and reflected by a color sample, then quantifies it into color data that can be interpreted by color management software. A spectrophotometer can measure a wide range of materials including synthetic or natural fabric, liquid, plastic, paper, metal, painted substrates, and in some cases, multi-colored materials.

Spectrophotometers contain a light source, a monochromator to select specific wavelengths of light, a sample holder, and a detector. The monochromator disperses the light into its component wavelengths and directs a specific wavelength towards the color sample. The detector then measures the amount of light that is transmitted or absorbed by the sample, which can be used to determine the concentration of specific colorants or dyes within the sample. The resulting data enables color replication in industrial settings.