By Rik Mertens, Global Application Manager at Datacolor

Can Digital Color Management Make It Easier to Be Green?

Traditional methods for managing the color of products takes time, produces waste and can require extensive transportation of samples. As such, digital color management can play an important role in achieving sustainability goals, not only in industries like textiles, cosmetics, food and beverage, plastics, or paints and coatings, but in any field where brand recognition and perception of product quality is at stake. Creating more sustainable colors or reformulating existing ones in order to meet regulations without sacrificing quality is often seen as a difficult task, especially since the trial-and-error process of visual evaluation alone can be costly.

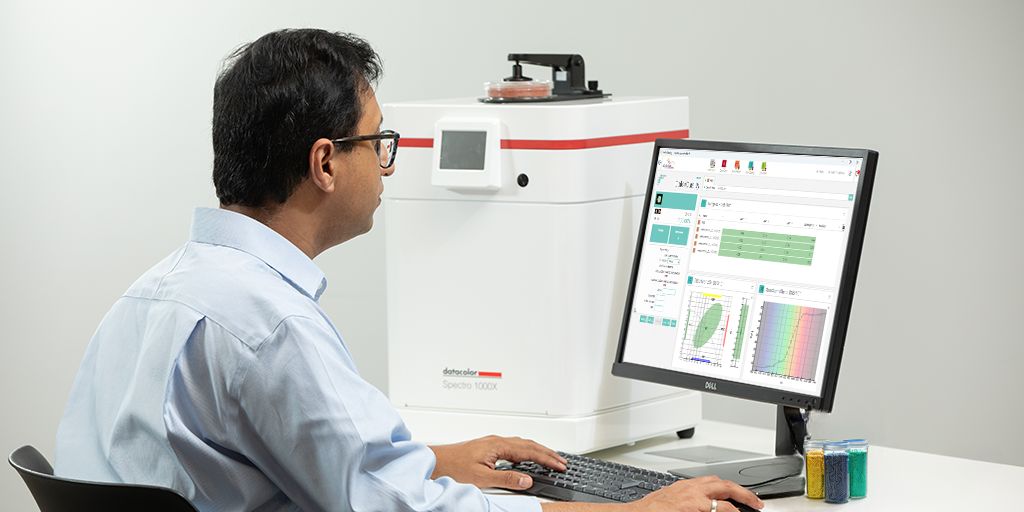

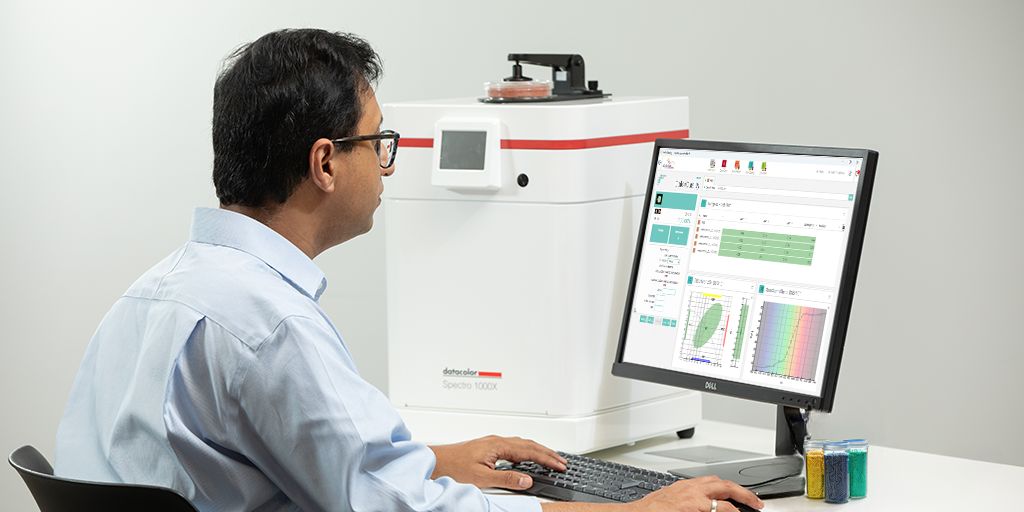

Digital color management technology offers a practical solution to many of the challenges involved. By combining spectrophotometer measurements, high-precision formulation software, centralized data and automation tools, manufacturers are finding more effective ways to reduce waste and costs — while meeting or exceeding sustainability goals.

What’s Driving Demand for “Green Chemistry”?

Consumer demand, recent supply chain shortages and the personal values of some company owners all play roles in encouraging manufacturers to reconsider everything from the quantity of resources they consume to the amount of waste they create. The primary force behind the most significant changes, however, is often governmental regulations.

“There are a lot of very, very good actors out there who are doing a lot of good things, but industry hasn’t moved the needle far enough. And so governments have taken it upon themselves to put rules and regulations in place,” said Rick Horwitch, chief of supply chain and sustainability strategy for Bureau Veritas, an audit and certification services company.

According to Horwitch, the biggest sustainability challenge facing many companies, especially those further down the supply chain, is an educational gap.

“It’s not that they’re not doing the right thing. In many cases, they just don’t know what to do. A lot of these rules are very complicated and confusing, and there’s no harmonization of regulations,” he said.

Within the United States alone, for example, manufacturers may have to contend with both federal regulations and those imposed by individual states. If the same company also does business in the European Union, it will need to comply with additional rules imposed both by the international organization and its member countries.

Compliance Hot Spots

Horwitch identified three broad categories that are top of mind for manufacturers today:

- Traceability and transparency — There’s increasing demand from regulators around the world to know what’s going on at every stage of the supply chain. This includes everything from where raw materials come from to the way workers are treated in vendor facilities.

- Climate and environment — Whether it’s science-based target initiatives (SBTIs) or commitments to decarbonization, reducing our collective impact on the planet is becoming a higher priority. Governments aren’t alone in demanding this kind of change; many major retailers and brands now require their partners to adhere to standards that go beyond compliance with current legislation.

- Extended producer responsibility (EPR) — Manufacturers are increasingly being held accountable not only for the responsible production and distribution of their products, but for the impacts they have throughout their entire lifecycle.

Concerns in any of these categories can lead to regulation or outright bans – with significant impacts on color formulations.

For example, until recently, paint and coating formulas, furniture, flooring products and some cosmetics used volatile organic compounds (VOCs) such as benzene or formaldehyde to prevent mold growth and keep substances in liquid form. Another VOC, acetaldehyde, was used in dye production. Unfortunately, these toxic organic compounds have the potential to cause health problems when released into the air.

Although regulations vary by country and region, there’s been significant increases in both mandatory labeling requirements and outright bans on some VOCs, accelerating the industry’s movement toward more eco-friendly products.

The need to eliminate VOCs has created challenges by requiring the reformulation of many existing products. Formulation software helps manufacturers to match thousands of colors while favoring specified ingredients. For example, if mineral pigments are favored over inorganic pigments, that can be set as a formulation parameter.

Being able to specify ingredients when calculating formulations not only helps manufacturers to meet environmental regulations, it also enables them to meet the needs of customers based on criteria such as cost, hiding power, contrast ratio, film thickness and more. Supporting customer requests while keeping the formula within regulatory limits is vital to success.

Waste Reduction

Digital color management tools help color-conscious manufacturers reduce waste in many ways. With a streamlined digital process in place, they can increase productivity, reduce the time it takes to produce a color by up to 50%, improve first-shot color matches by up to 80%, and minimize the amount of waste being created by error-prone, purely visual color evaluation.

For example, one source of waste in the paint industry comes from making paint samples in a lab when formulating new recipes. For many architectural manufacturers, manually perfecting a single formula can take multiple attempts and each of the resulting samples is up to 500 ml of paint. Now multiply that by perhaps 2,000 colors in a fan deck, and that’s thousands of liters of paint, much of which ultimately may end up in the trash.

Granted, with the right software, some paint samples can be worked into other formulations using “recycle” features. But greater precision of formulas at the onset can save manufacturers time, money, labor and raw materials that could be used more efficiently elsewhere.

In addition, architectural paint manufacturers who automate the sample dispensing process can achieve greater accuracy, and in some cases, the volume of a sample can be reduced by 70%. Not only does that save resources and prevent paint from ending up in landfills, it also reduces the size of the can needed, therefore saving even more resources.

With a combination of automated dispensers and digital color management software such as Match Pigment, the process of formulating samples and dispensing them could be a lot more sustainable, not only benefiting the environment, but the manufacturer’s bottom line as well.

A similar approach to color management can benefit many other industries. In textiles, for example, digital color management can optimize dye formulas to prevent overdevelopment of colors and conserve resources as well as dramatically reduce time and shipping costs associated with shipping physical lab dips for approval.

Digital management is also a boon to brands that require consistent color across a wide variety of merchandise. Sports teams are a classic case where signature colors need to match across items as diverse as apparel, promotional bags and backpacks, mugs, glasses, water bottles, pins, toys, keychains, accessories, and even food and beverage packaging.

“What I hear and see more and more, particularly from some really well-known brands, is that the color of their products says something about who they are. The matching of that color is absolutely critical. So you can’t do these things in the 20th century mode. You have to be in a digital mode,” Horwitch said.

Cost Management

Sustainability goals are often synonymous with higher costs in the minds of producers and consumers. This is partly because embracing eco-friendly processes requires the development of innovative and revised formulations. These can’t be perfected overnight and require resources to produce — both in the form of raw materials and historically scarce labor with the necessary skills.

“Production mistakes can have significant financial consequences,” said Albert Busch, president and CEO of Datacolor®. “The more confident you can be in your color matching process, the more time and money you can save.”

Staying focused on sustainability without breaking the bank is another area where digital color management offers relief. In addition to the recycling strategies already discussed herein, a digital system can streamline daily operations by ensuring consistent practices and automating processes where possible. When data is shared across production facilities, all producers work from the same set of optimized formulations and calculations.

“It’s important to look at sustainability from an economic and ecosystem perspective,” Horwitch advised. “You can recover your costs. You just need to think about it in the right way.”

Digital management can also minimize the impact of scarce labor. For example, an intuitively designed system can reduce the time needed to train new workers. In addition, it allows essential notes to be attached to individual formulas, ensuring that critical knowledge doesn’t get lost over time.

Three Challenges, One Solution

Digital color management technology offers a practical solution to the challenges of sustainability in many different forms of manufacturing. It can address issues related to waste reduction, cost and resource management, and compliance with environmental regulations.

By leveraging a combination of spectrophotometer measurements, high-precision formulation software, centralized data across facilities and automation tools, manufacturers can achieve sustainability goals without sacrificing quality. This approach enhances efficiency, reduces resource wastage, and streamlines operations, making it a business-friendly way to embrace sustainability.

This article originally appeared in WTiN.